Popular Soundproof Insulation Solutions for Professional Installations

Discover trusted products favored by experts to achieve superior soundproofing results in residential and commercial projects.

Soundproof insulation products are essential components in creating quieter indoor environments by reducing noise transmission through walls, ceilings, and floors. These materials are designed to absorb, block, or dampen sound waves, making them suitable for various residential, commercial, and industrial applications. When selecting soundproof insulation, it is important to consider the specific noise issues, the space's configuration, and compatibility with existing structures.

Soundproof insulation products are essential components in creating quieter indoor environments by reducing noise transmission through walls, ceilings, and floors. These materials are designed to absorb, block, or dampen sound waves, making them suitable for various residential, commercial, and industrial applications. When selecting soundproof insulation, it is important to consider the specific noise issues, the space's configuration, and compatibility with existing structures.

Top Overall Option

Acoustic Insulation Batts

Acoustic insulation batts are versatile and easy-to-install materials that fit between wall studs, ceiling joists, or floor joists. They are typically made from dense mineral fibers or fiberglass, which help absorb sound waves and reduce noise transmission. These batts are suitable for a variety of applications and can be cut to size for a snug fit, providing an effective barrier against airborne sound. Proper installation, including sealing gaps and overlaps, enhances their soundproofing capabilities. They are a popular choice for homeowners and contractors seeking a straightforward solution for sound insulation in walls and ceilings.

Types of Products For Soundproof Insulation Installations

Fiberglass Insulation

Fiberglass insulation is widely used for soundproofing due to its lightweight nature and good sound absorption qualities.

Mineral Wool Batts

Mineral wool batts offer dense, fire-resistant soundproofing options suitable for various building applications.

Mass Loaded Vinyl

Mass loaded vinyl is a flexible, dense material used to add mass and block sound transmission in walls and ceilings.

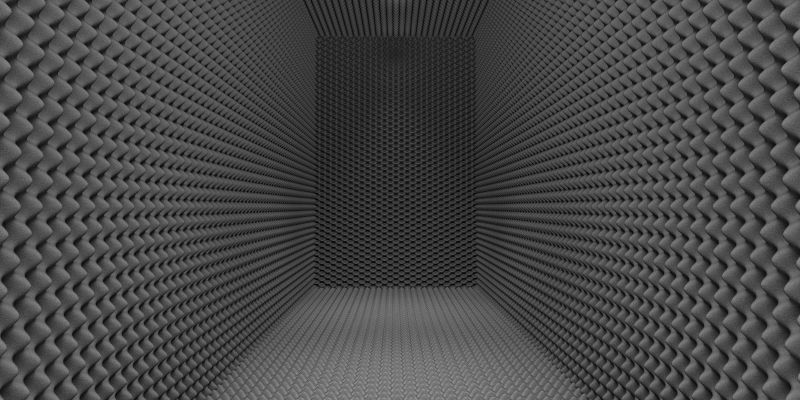

Acoustic Foam Panels

Acoustic foam panels are designed to absorb sound waves and reduce echo within a room, ideal for studios or home theaters.

Resilient Channels

Resilient channels decouple drywall from framing, reducing sound vibrations and improving soundproofing performance.

Soundproof Drywall

Specialized drywall with enhanced mass and damping properties helps improve sound insulation in walls and ceilings.

Decoupling Clips

Decoupling clips isolate drywall from framing to minimize sound vibrations and improve overall soundproofing.

Acoustic Sealant

Acoustic sealant is used to seal gaps and cracks around insulation and panels to prevent sound leaks.

Soundproof Curtains

Heavy, dense curtains designed to block airborne noise and reduce sound transmission through windows and doors.

Green Glue Noiseproofing Compound

Green Glue is a damping compound applied between layers of drywall to reduce sound vibrations and improve insulation.

Acoustic Underlayment

Underlayment materials installed beneath flooring to dampen impact noise and airborne sound transmission.

Resilient Sound Clips

Resilient sound clips help decouple walls and ceilings, reducing the transfer of sound vibrations.

Foam Bass Traps

Bass traps are specialized acoustic panels that absorb low-frequency sounds, improving room acoustics.

Soundproof Door Sweeps

Door sweeps seal gaps at the bottom of doors to block sound leaks and improve room acoustics.

Flexible Acoustic Barriers

Flexible barriers made from dense materials help block sound transmission through walls and partitions.

Popular Choices

A common choice for soundproofing due to its availability and ease of installation.

Effective for adding mass and blocking sound in walls and ceilings.

Widely used in studios and home theaters for sound absorption.

Popular for their density and fire-resistant properties.

Commonly used between drywall layers for damping vibrations.

Frequently chosen for new constructions and renovations for enhanced sound control.

Popular for decoupling drywall and reducing sound vibrations.

Often used to seal gaps and improve overall soundproofing effectiveness.

A favored option for blocking airborne noise through windows.

Commonly used in conjunction with drywall to enhance sound isolation.

Popular beneath flooring for impact noise reduction.

Effective for sealing gaps at door bottoms to prevent sound leaks.

Frequently used in recording studios and listening rooms for low-frequency absorption.

Chosen for their ease of installation and effective sound blocking.

The installation process typically involves choosing the right type of insulation, preparing the surfaces, and properly fitting the materials to ensure maximum effectiveness. Different products offer varying levels of sound absorption and blocking capabilities, which can be tailored to the noise reduction needs of each space. Proper installation and sealing are crucial to prevent sound leaks and achieve optimal performance.

In addition to traditional insulation materials, there are specialized soundproofing products such as acoustic panels, mass loaded vinyl barriers, and resilient channels that can be integrated into existing structures or new builds. These options provide versatile solutions for achieving sound control, whether in home theaters, recording studios, or shared walls in apartment complexes. Careful consideration of the product's properties and installation requirements can help optimize noise reduction outcomes.

Key Buying Considerations

- Assess the primary noise source to determine if the focus should be on sound absorption, blocking, or damping.

- Consider the space's structural compatibility with different insulation types and installation methods.

- Evaluate the R-value or insulation thickness for thermal considerations if relevant.

- Check the material's density and mass to ensure effective soundproofing properties.

- Determine whether the solution requires decoupling elements to minimize vibrations.

- Review the ease of installation and whether professional help is needed.

- Examine the fire resistance and safety ratings of the materials used.

- Identify if additional sealing or acoustic treatments are necessary for optimal performance.

- Consider the long-term durability and whether maintenance or replacement might be needed.

- Factor in the budget constraints while balancing soundproofing effectiveness and material quality.

- Look into compatibility with existing wall, ceiling, or floor structures.

- Assess the potential impact on room aesthetics and whether decorative elements are compatible.

- Research product reviews and user feedback for real-world insights.

- Verify that the products meet relevant safety and building code standards.

- Determine if the products are suitable for the specific application environment, such as high humidity or industrial settings.